The implementation of quick clamping tools features several pros in contemporary sheet metal fabrication:

Sheet metal bending solutions are related in that their end purpose is to remodel metal constructions into the desired kinds. On the other hand, they vary in operation.

Given that the founder of MachineMFG, I have devoted around ten years of my job on the metalworking business. My intensive knowledge has authorized me to be an authority during the fields of sheet metal fabrication, machining, mechanical engineering, and machine tools for metals.

The Tool Setup Optimizer solution checks which parts you need the same tools for And exactly how the tool stations might be greatest merged. This enables you to bend the utmost variety of areas with just one tool set up.

You can use a bending calculator accessible on-line to calculate the design variables and considerations. We'll go over these in additional sections. Furthermore, you must specify the apparent Proportions and tolerances in the design. Stage two: Preparing Your File

TruBend Sequence 7000 The TruBend Series 7000 is a prime example of fantastic interaction among guy and machine. Superior speeds and acceleration values about the bending machine at the side of exceptional operate circumstances be certain very first-level Total efficiency.

Air Bending: The most typical approach where by the metal isn’t fully forced in to the die. This process allows for extra overall flexibility in bend angle.

Y Axis: This axis governs the vertical movement in the upper beam (ram). Given that the ram descends or ascends, it instantly influences the bend angle. In the course of the bending process, it’s vital to the operator to guarantee alignment concerning the Y1 and Y2 axes (still left and ideal cylinders of your ram).

Aluminum is ductile and easy to type in various styles and curvatures. It provides outstanding corrosion resistance and energy-to-bodyweight ratio.

Extra characteristics: CNC systems, advanced tooling setups, and automated product managing systems add to enhanced bodyweight.

Some elastically deformed product throughout the bending line tries to return to its first form and lead to spring again. In addition, variables like used process, radius, and material Qualities also have an impact on the spring again.

Even though confined in capacity and precision compared to driven options, they provide unparalleled simplicity and they are beneficial for rapid, uncomplicated bends or prototyping do the job.

This twin-stage performance boosts both equally safety and precision from the bending operation. The pedal change also controls the retraction of the ram following the bend is complete, returning the press brake to its open up posture.

This adaptable machine is actually a cornerstone in numerous metalworking industries, playing a significant position in production components to get a wide array of purposes. From automotive overall body read more panels and aerospace structural factors to HVAC ductwork and architectural attributes, press brakes are indispensable in shaping the metal environment all over us.

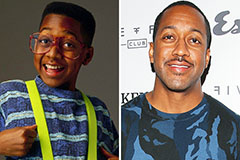

Jaleel White Then & Now!

Jaleel White Then & Now! Andrew Keegan Then & Now!

Andrew Keegan Then & Now! Marques Houston Then & Now!

Marques Houston Then & Now! Bill Cosby Then & Now!

Bill Cosby Then & Now! Erika Eleniak Then & Now!

Erika Eleniak Then & Now!